Building Resilient Oil-and-Gas Infrastructure Through Future-Ready Networking Solutions

The oil and gas industry demands equipment and network connections to withstand the harshest conditions. Any lapse in such environments can lead to decreased operational efficiency, compromised on-site safety, and a decline in competitiveness. This emphasizes the necessity of reliable, efficient, and future-proof solutions within this sector, making it a critical priority.

A compelling case study involves Streamline Innovations, which faced the daunting task of extracting hydrogen sulfide (H₂S) from gas and transforming it into agricultural-grade sulfur. This required precise remote control over chemical reactions traditionally supervised on-site. By adopting futureproof networking solutions and robust devices, Streamline Innovations achieved reliable connectivity and IT/OT convergence. This advancement led to a remarkable 75% reduction in labor costs, improved uptime, and enhanced operational performance.

Their success underscores the significance of futureproof networking technologies and reliable products in minimizing hidden costs. It vividly portrays the pivotal role of each networking device's reliability in ensuring a high-quality output from oil and gas systems in the long term.

Exploring Real-World Applications

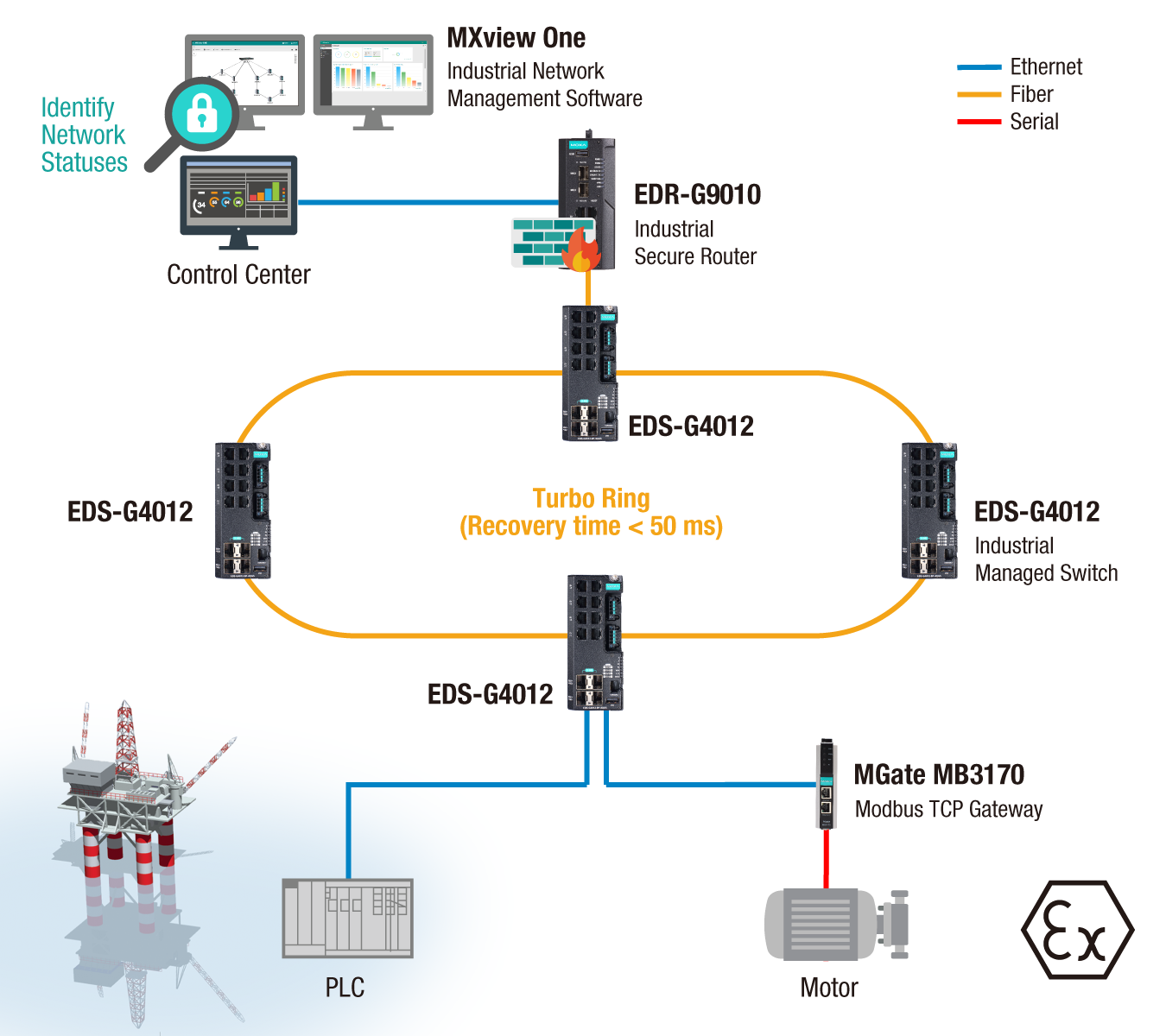

Application 1: Reliability on the Seas—Offshore Oil Drilling

In offshore oil drilling, where synchronized monitoring and operational support pose challenges, dependable communication, and reliable monitoring networks are indispensable. Disruptions in this harsh environment can lead to costly production stoppages due to equipment failures. To address these challenges, a robust and reliable network infrastructure is essential. Products designed for durability in demanding environments, emphasizing ruggedness, become crucial. Incorporating redundancy in the network architecture minimizes downtime and enhances operational efficiency. Certifications like DNV, Class I Division 2 (CID2), and ATEX Zone 2 become pivotal for operation in explosive gas environments, extreme temperatures, corrosive conditions, and vibrations.

Implementing these measures ensures offshore oil-drilling operations function effectively, even amidst temperature fluctuations, corrosive conditions, and continuous vibrations. It eliminates costly manual operations and reduces complexity and operational expenses, ensuring sustainable production 24/7.

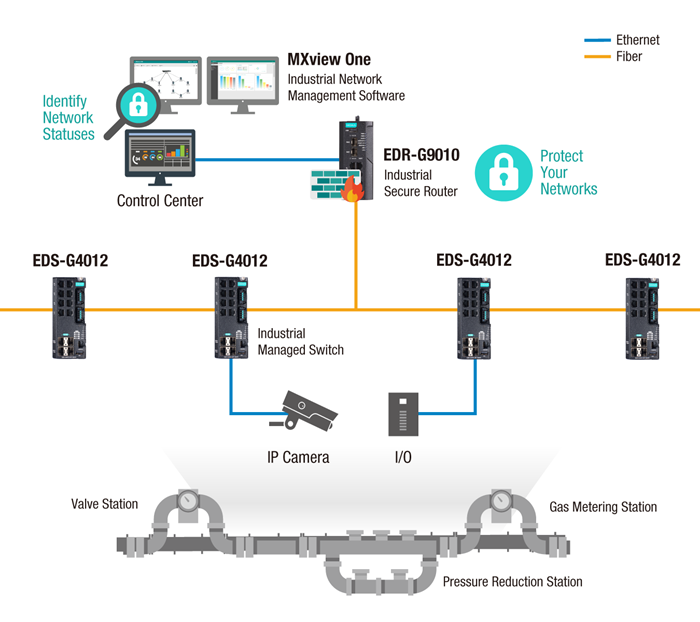

Application 2: Monitoring the Lifeblood—Oil-and-gas Pipelines

Ensuring dependable transportation of large volumes of oil and natural gas across vast pipeline networks spanning thousands of kilometers is crucial. Robust, scalable, and flexible fiber optic Ethernet networks are vital for identifying, preventing, and resolving pipeline issues, including leaks and damages. With its reliability and ability to cover long distances, Ethernet networks enable seamless remote control and monitoring of essential parameters.

Oil-and-gas pipelines in unstaffed areas necessitate reliable devices and cybersecurity measures. Authentication and access control within networking devices are crucial to ensuring both seamless and secure data transmission.

In summary, robust hardware and software are essential for constructing resilient network architectures. The interconnectedness between reliability and security guarantees the continuous flow of oil and gas within pipeline networks.

Overcoming Networking Hurdles for a Smart Digital Future

Product Highlight

"EDS-G4012 Series"

- Developed according to the IEC 62443-4-1 and compliant with the IEC 62443-4-2 industrial cybersecurity standards

- Support for IEEE 802.3bt PoE for up to 90 W output per port

- Increased bandwidth capabilities with fiber SFP slots supporting up to 2.5 Gbps

- Wide range of power input options for flexible deployment