Intralogistics Automation Enhanced by Balluff Technology

In intralogistics, where the movement of raw materials to finished goods demands fast throughput, precision, and traceability, efficiency is not just a goal, but a necessity. Automating key processes such as warehouse management, inventory management, and material handling, including conveying, transporting, loading, unloading, sorting, and order picking, is critical to increasing availability and uptime, reducing costs, and ultimately improving Overall Equipment Effectiveness (OEE).

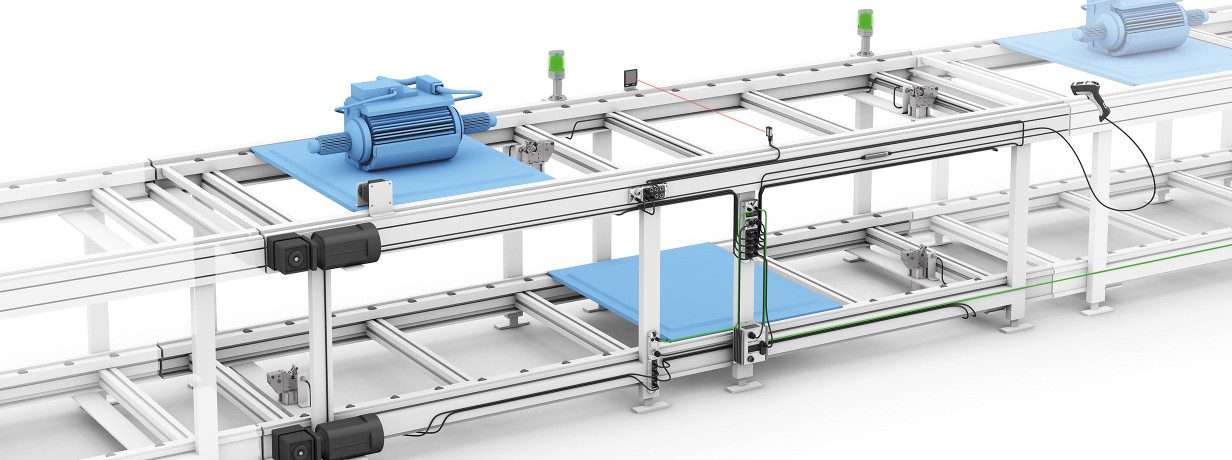

Components and solutions for automated intralogistics operations

Automation components and best-in-class consulting expertise

Spotlight applications in intralogistics automation

Discover how we can improve your systems and intralogistics operations to effectively meet your challenges.

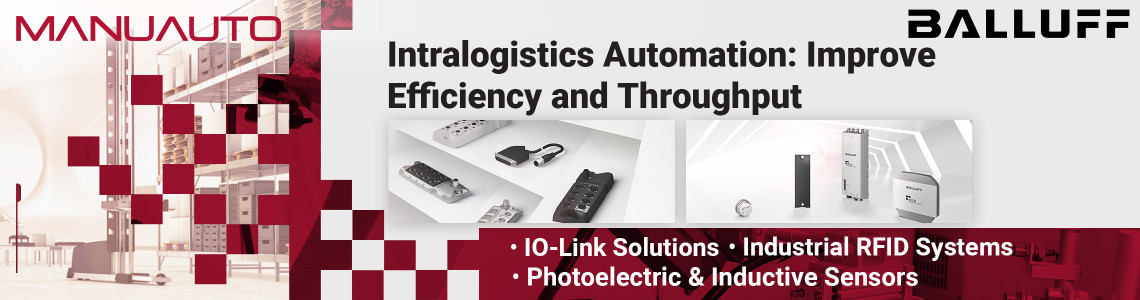

Precise optical detection in intralogistics

BOS photoelectric sensors ensure reliable object detection in tight spaces with easy installation and versatile mounting options.

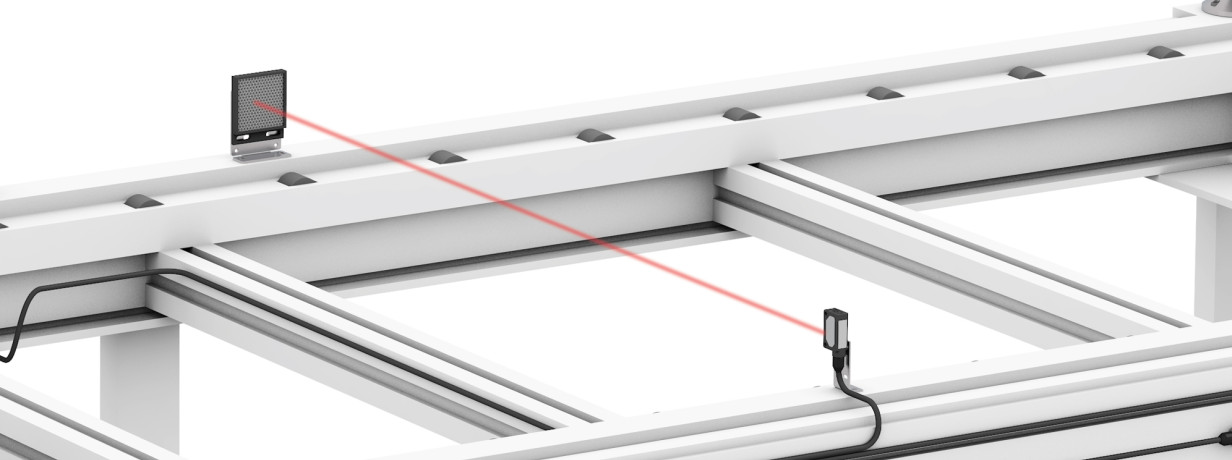

Energy-efficient movement

BNI network modules with IO-Link enhance energy efficiency in conveyor systems.

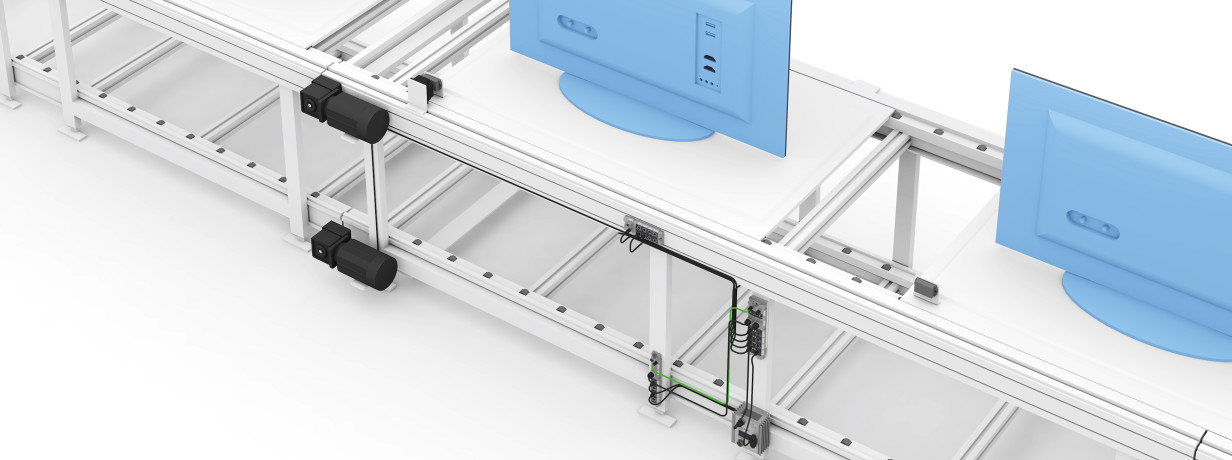

High-speed pallet tracking

BIS industrial RFID systems offer high-speed, accurate tracking and traceability of stock and pallets, even in compact applications.

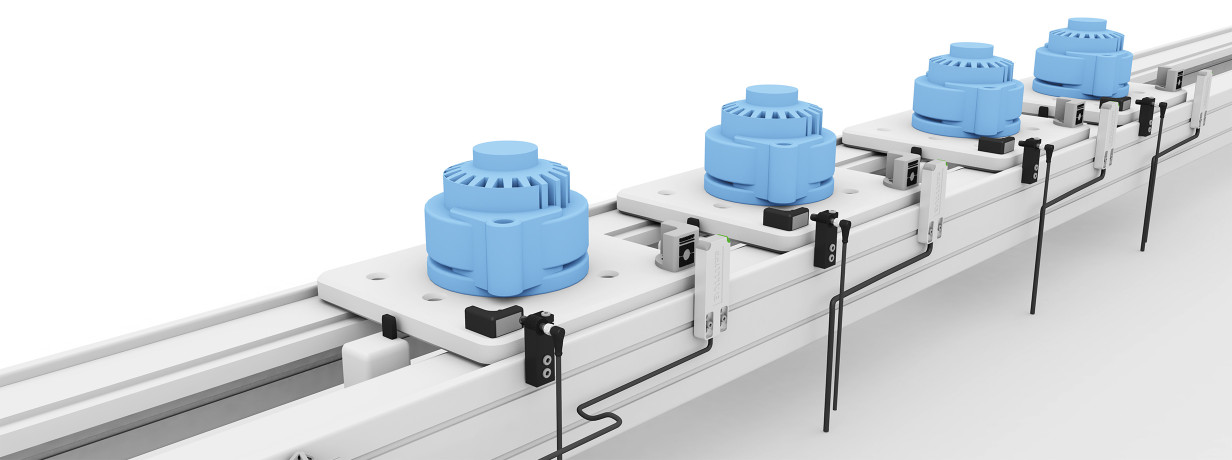

Reliable object detection

BES inductive sensors provide simple, flexible tracking solutions, offering a variety of sizes and designs for flexible integration.

Traceability, Speed, and Quality in Each Area of Intralogistics Automation

Automated storage and retrieval systems: improving efficiency and accuracy

Transportation and conveying solutions: advancing material flow

Automated sorting and picking systems: correctly assembled - whether partially or fully automated

Components and solutions bringing distinct advantages to your roles in intralogistics automation

Machine builders

- Durable and cost-efficient solutions for optimal system and machine functionality, contributing to enhanced product quality and yield.

- Expert consultation for selecting and integrating the best components to improve system uptime and efficiency.

- Custom automation components fit specific machine designs.

Production managers

- Solutions that improve throughput, accuracy, and consistent operation.

- Seamless integration with existing production lines for enhanced control and system performance.

- Condition monitoring and predictive maintenance to minimize downtime and ensure system uptime.

Warehouse managers

- RFID and sensor technology for accurate goods tracking and tracing.

- Efficient warehouse management through solutions that optimize storage and retrieval processes.

- Energy-efficient operations with IO-Link technology for cost savings and sustainable energy use.

BNI IO-Link Solutions

IO-Link's real-time data enhances diagnostics and production line flexibility across manufacturing operations.

BOS Photoelectric Sensors

Reliable object detection of all kinds of goods and accurate fill level monitoring on conveyor systems.

BIS Industrial RFID Systems

Reliable tracking and tracing of goods, key for inventory management and product quality.

BES Inductive Sensors

Efficient and compact, perfect for object detection in confined spaces for maximum throughput at low cost.

Explore industries where intralogistics takes center stage

Packaging and processing

Discover how Balluff's sensor and networking solutions

enhance intralogistics operations in the packaging industry, improving process

efficiency and OEE.

Automotive production

Explore how Balluff supports efficient intralogistics and

production processes from foundry work to final assembly.

Battery manufacturing

Learn about Balluff's role in streamlining intralogistics

processes from electrode manufacturing to module and pack assembly.

Electronics industry

See how Balluff’s components enable fast, reliable, and

cost-effective production of electronics.