Robustel Enhancing Smart Mining Operations with IoT

Enhancing Mining Operations with IoT: A Revolutionary Solution for Mining Truck Monitoring

Transforming mining operations with IoT technology represents a significant advancement in addressing the industry's challenges. By focusing on mining truck monitoring, we explore how IoT and 5G are reshaping safety, efficiency, and cost-effectiveness in this critical sector.

Understanding the Mining Sector

Mining operations are often complex and remote, presenting unique challenges. Limited visibility and noise-related issues in truck operations are key safety concerns, contributing to collision risks and worker safety hazards.

Addressing Visibility and Noise Challenges

Operating in rugged terrains with limited visibility poses safety risks, while noise levels hinder effective communication and situational awareness. These challenges increase the potential for accidents and damage to equipment and infrastructure.

Mitigating Collision Risks and Enhancing Safety

The presence of multiple trucks and workers within mining sites heightens collision risks, especially due to blind spots. Ensuring worker safety amidst moving vehicles is a top priority for mining companies.

Leveraging 5G and IoT for Mining Truck Monitoring

5G and IoT technologies offer unprecedented capabilities in real-time monitoring and management of mining truck operations. Companies can optimise safety, operations, and productivity through interconnected devices, cameras, and sensors powered by Robustel 5G IoT routers.

1. Real-time Monitoring for Enhanced Safety

IoT enables continuous monitoring of truck location, status, and performance. Equipping trucks with sensors allows for instant alerts in hazardous situations, enabling timely intervention to prevent accidents and injuries. Geofencing mechanisms further ensure adherence to safe zones.

2. Predictive Maintenance for Operations Optimization

IoT facilitates predictive maintenance by collecting real-time engine performance, fuel consumption, and tire wear data. This proactive approach minimizes downtime and extends truck lifespan. Data analytics offer insights for process optimization and productivity improvement.

3. Efficient Asset Utilization and Resource Allocation

IoT-driven monitoring systems provide accurate data on truck utilization, idle time, and payload capacity. Analyzing this information allows companies to optimize asset utilization and allocate resources effectively, resulting in cost savings and operational efficiency.

In Conclusion

IoT technology is revolutionizing mining operations, particularly in truck monitoring. By tackling safety concerns, optimizing maintenance, and improving resource management, IoT solutions are driving safer, more efficient, and sustainable mining practices. As the industry continues to embrace IoT, we anticipate further advancements and transformative outcomes, ensuring a brighter future for mining operations.

Recommend Products

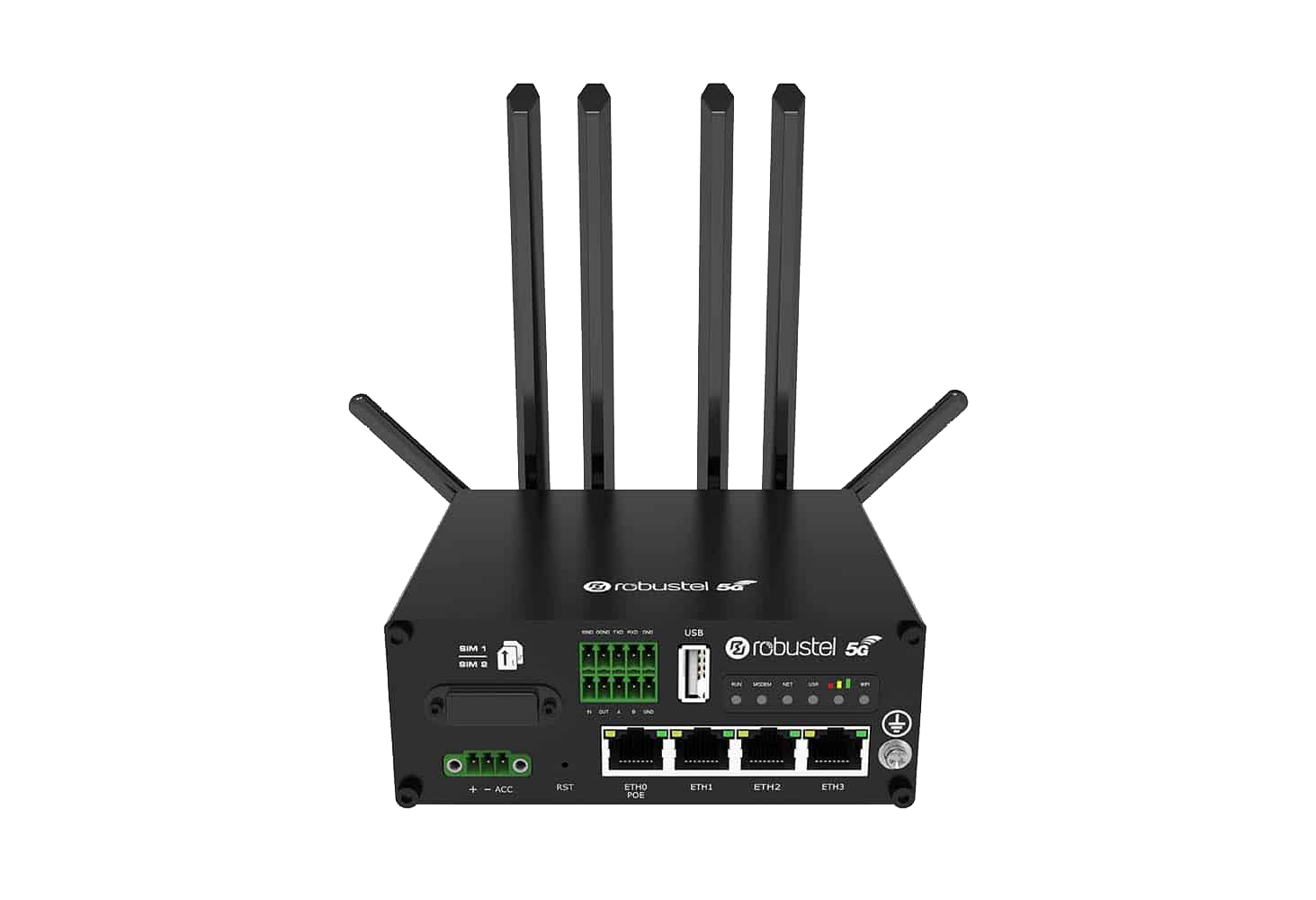

R5020 5G IoT Router

- Global 5G/4G/3G cellular connections

- Supports Ethernet, Wifi and 4G/5G internet with auto-failover

- Very cost-effective industrial 5G router solution

- Fully programmable Operating System with well-documented SDK

- Multiple VPN options are available, including DMVPN & IPSEC

- GNSS, ignition sense & E-mark make R5020 ideal for vehicles

- Free cloud management platform – RCMS

- Robust metal enclosure with small footprint – DIN-rail + wall mount options