Ultrasonic Position Sensor Directly Monitors Workpiece Clamping

A Milestone in the Field of Metalworking

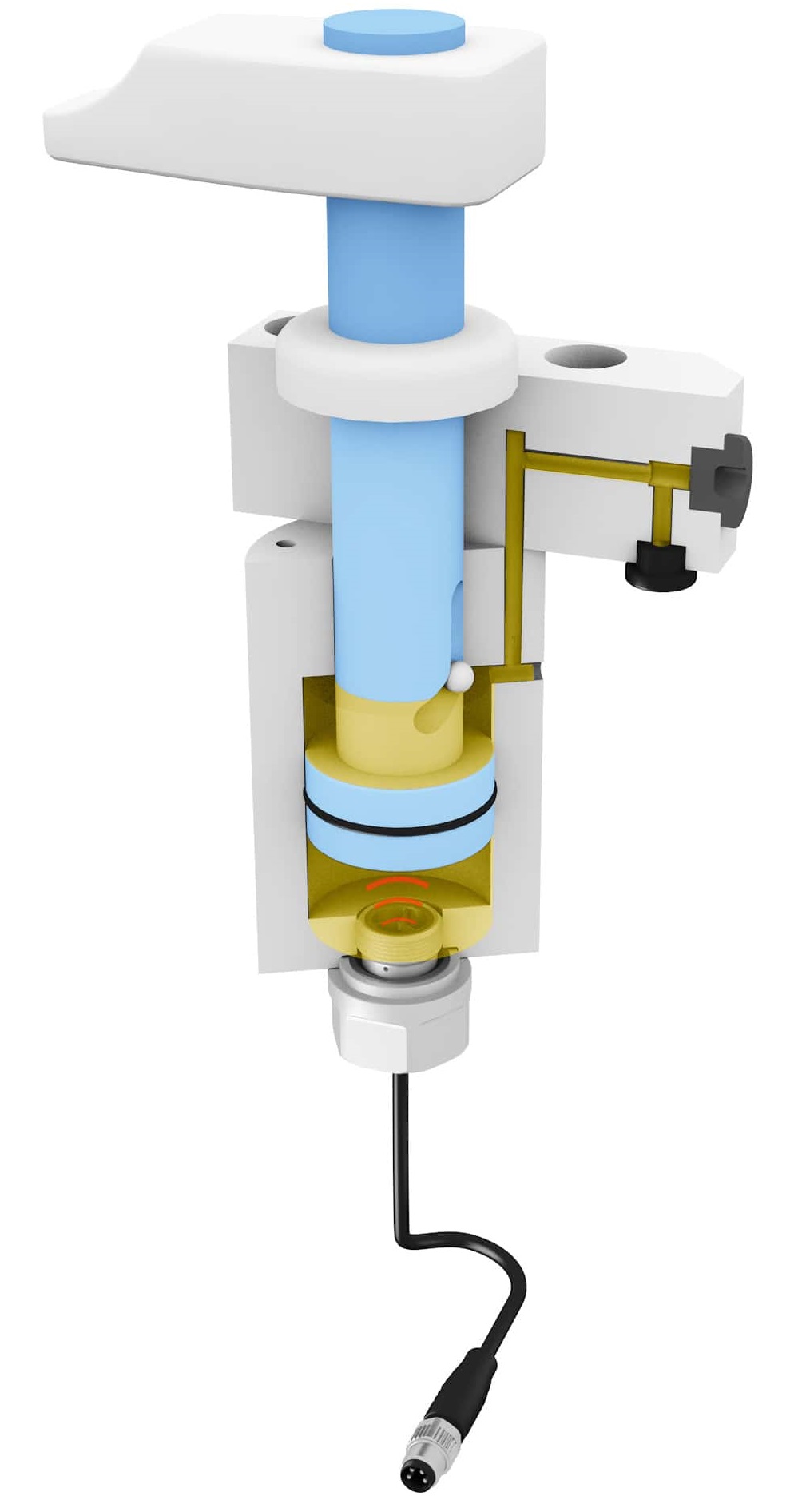

In the realm of metalworking, precise workpiece clamping is paramount,

and ultrasonic sensors from Balluff are rewriting the rules. The introduction

of the BFD ultrasonic position sensor with media contact takes workpiece

clamping monitoring to new heights.

Traditionally, monitoring workpiece clamping relied on indirect methods, like measuring hydraulic fluid volume flow or monitoring piston end positions. These approaches often proved costly, inflexible, and less reliable. Moreover, they struggled to address the intricacies of both clamping status and travel simultaneously, falling short in meeting the ever-increasing demands for machine safety.

Here's where the Balluff ultrasonic position sensor shines. By emitting ultrasound into the hydraulic fluid, the BFD directly, continuously, and rapidly monitors workpiece clamping, offering reliable insights into clamping status.

Early detection of issues such as oil supply problems, casting errors, contour deviations, insertion errors, and deformed workpieces becomes possible. Comprehensive clamping process monitoring even allows for spotting pressure fluctuations in the hydraulic unit, swivel mechanism defects, and faulty seals well in advance.

In essence, the BFD ultrasonic position sensor responds directly to customer demands, delivering innovation with the potential to become the industry standard.

Seamless Integration and Scalable Application

The sensor's compact design, customizable

standardized interfaces, and continuous automated compensation ensure

effortless integration and versatile "plug & play" use in various

media. When combined with Balluff's standard system components, it forms an

exceedingly cost-effective, comprehensive solution.

Additional invaluable information is accessible through IO-Link, including device status monitoring, device temperature, and signal quality. This empowers you to detect critical medium changes, such as the presence of air or particles in the hydraulic system, promptly. With Balluff's BFD ultrasonic position sensor, workpiece clamping reaches new levels of efficiency and reliability, ushering in a wave of innovation that sets a new industry standard.

Key Features

- Economic integration thanks to the compact design, standardized system components, and interfaces. -->

- Flexible integration via IO-Link, as an analog transmitter, or as a two-stage switch

- High-performance measurement over the entire measuring range of 0...80 mm: high repeatability of ≤ 100 µm, linearity deviation of ±250 µm, resolution IO-Link 1 µm / analog 12-bit, measuring rate IO-Link 500 Hz / analog 1000 Hz

- High-pressure resistance up to 350 bar

- Protection class IP67 and operating temperature 0...85 °C

- Continuous compensation to adapt the measurement to the type, composition, and quality of the hydraulic fluid

- Firmware functions to provide additional data for condition monitoring