Unveiling the Vital Role of CIP Safety in Automation Protocols

CIP Safety, a pivotal communication protocol within industrial automation, plays a significant role in upholding the safety of machinery, equipment, and processes. As part of the expansive Common Industrial Protocol (CIP) family, crafted by ODVA, a global authority in trade and standard development, CIP Safety ensures that the exchange of data amid safety devices, controllers, and other components remains secure.

At its core, CIP Safety facilitates real-time communication of safety-critical data. Think of emergency stops, safety interlocks, and safety status updates swiftly traversing diverse devices in manufacturing and processing setups.

Key Elements of CIP Safety

- Safety Communication: CIP Safety shines in providing rapid and dependable communication for safety-focused data. It ensures safety messages flow promptly, guaranteeing the timely execution of safety measures.

- Deterministic Behavior: This protocol prioritizes determinism. It's all about foreseeability and minimal latency in transmitting safety messages. This minimizes accident risks and ensures safety mechanisms perform as intended.

- Redundancy and Fault Tolerance: CIP Safety offers robust support for redundancy and fault tolerance. This means systems can persevere safely even when confronted with hardware or communication glitches.

- Safe States and Actions: The protocol defines safe states that systems can enter in response to safety events. It also outlines safe actions controllers and devices can take to prevent or mitigate hazards.

- Device Integration: Seamlessly integrating with other CIP protocols, like EtherNet/IP, allows the harmonious coexistence of safety and standard communication on one network.

- Certification: Devices and systems adopting CIP Safety often undergo rigorous certification processes. This certifies their adherence to safety standards and their capability to function in critical environments.

- Flexibility: CIP Safety's flexibility accommodates a spectrum of safety requirements. It caters to both simple safety tasks and intricate safety functions, making it an ideal fit for diverse industrial applications.

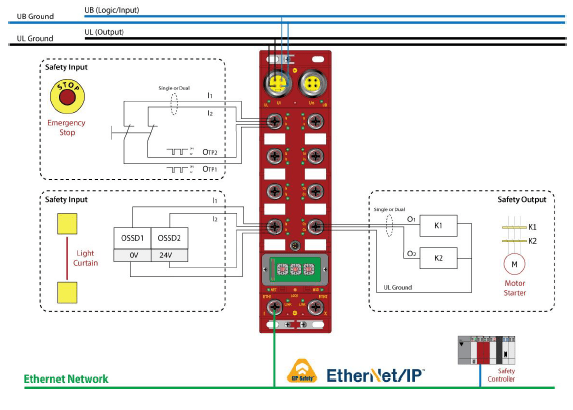

Examples of connections with an external CIP Safety Block

Industries such as manufacturing, automotive, and energy, where safeguarding personnel, equipment, and processes is paramount, have widely embraced CIP Safety. It enables the integration of safety systems into overall control structures, optimizing safety management in industrial settings. CIP Safety, an unsung hero in industrial automation, ensures that safety is paramount without compromising efficiency.

Product Details

CIP Safety I/O Module

BNI00HN

- EtherNet/IP CIP Safety interface

- IP67 protection class, TÜV and ODVA certified

- Connection of single and dual channel safety devices